It's provided me with a fun focus to work on the HDD Synth project this holidays, especially after a mountain biking accident has meant I've been stuck at home far more than I would normally be.

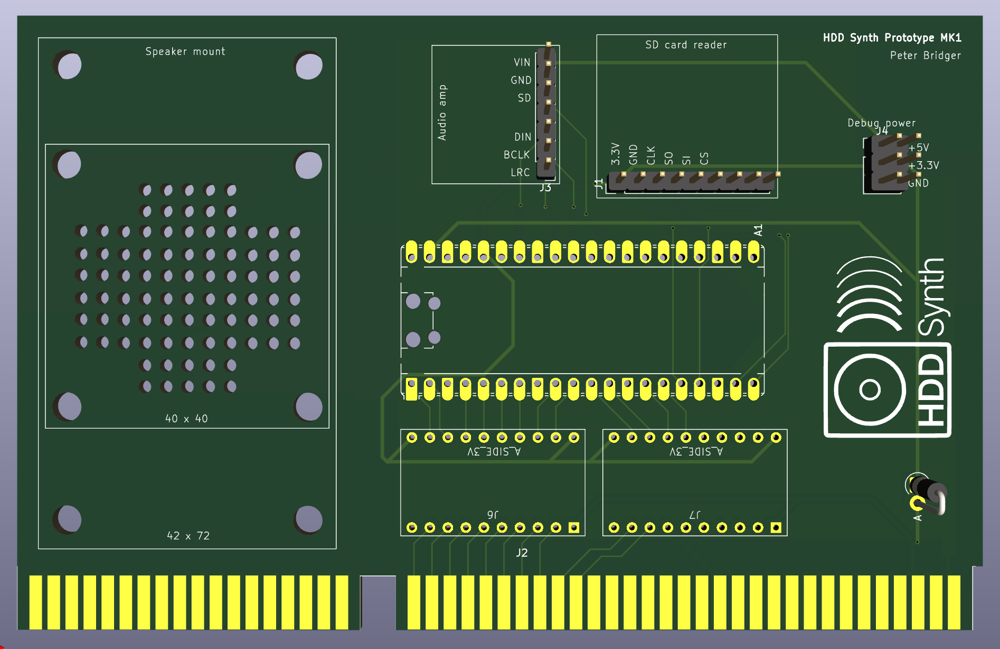

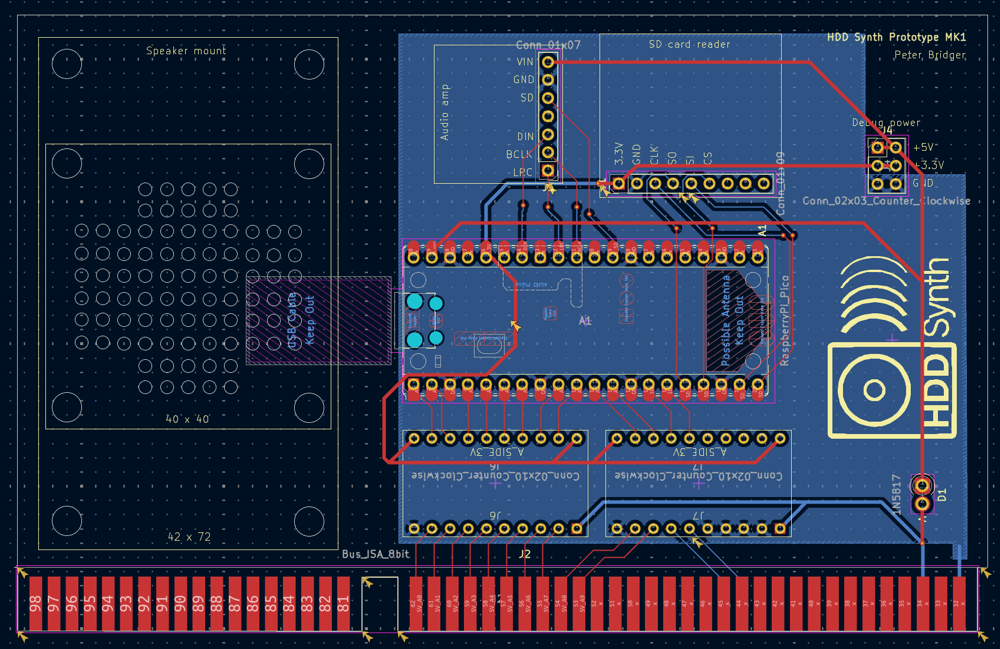

After a few days to tweaking and refining I've got to the point I believe I'm ready to send off my designs to be manufactured.

Learning how to design in KiCad has been an interesting and iterative process. Everytime I thought the board design was almost ready, I've learn something new which has led to further changes.

For instance by default all of the traces are 0.2mm wide, however I realised quite late in the day that for the power rails having traces 0.5 - 1mm would be more suitable so I made that change.

I was also going to use a few surface mount components, but I decide to keep everything as simple as possible for this first board. My biggest fear is that I'll make a mistake which will render the whole run defective, so keeping it simple is key.

Going with all through hole components meant that I needed to create my own footprint to allow for the level shifters to attach to the PCB instead of the original surface mount versions.

I was quite nervous about this, as if I got any of the measures wrong these chips wouldn't fit.

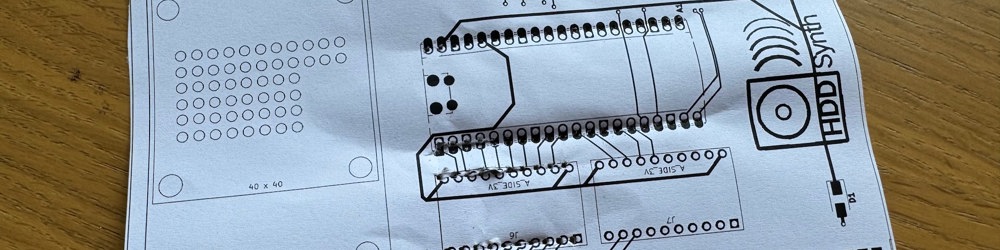

How do validate this? Let's print out the PCB and mount the components onto that